Slow Progress is Progress

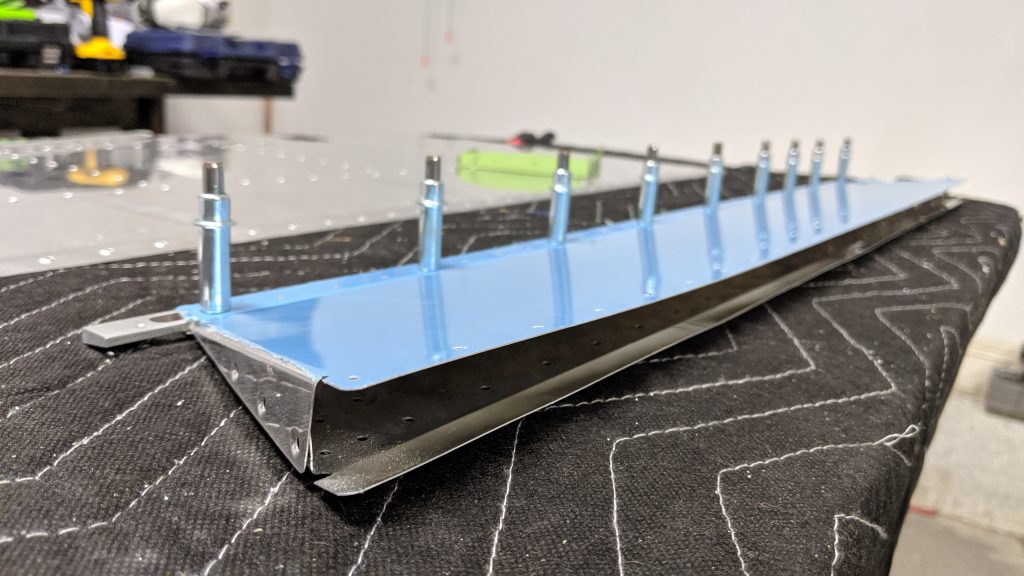

For various reasons I haven’t had a whole lot of time to dedicate to building the past couple of weeks, but I have gotten a little bit accomplished. My last update ended with me deciding to fabricate a spacer for the shear clip mishap. That’s done, and I’ve gotten a lot of other random small tasks done since then, like countersinking the front and rear spars, fabricating the elevator pushrod and horn assemblies, priming, and prepping the skins for the bonding of the foam ribs. Tonight was mostly more of the same. With the spars, ribs, and skins primed (more on this in a bit), all that was left to do tonight was fit assembly of the trim tab, trailing edge, and foam ribs, dimpling/countersinking of the trim tab spar, and prepping the trim tab skins for priming and bonding to the ribs.

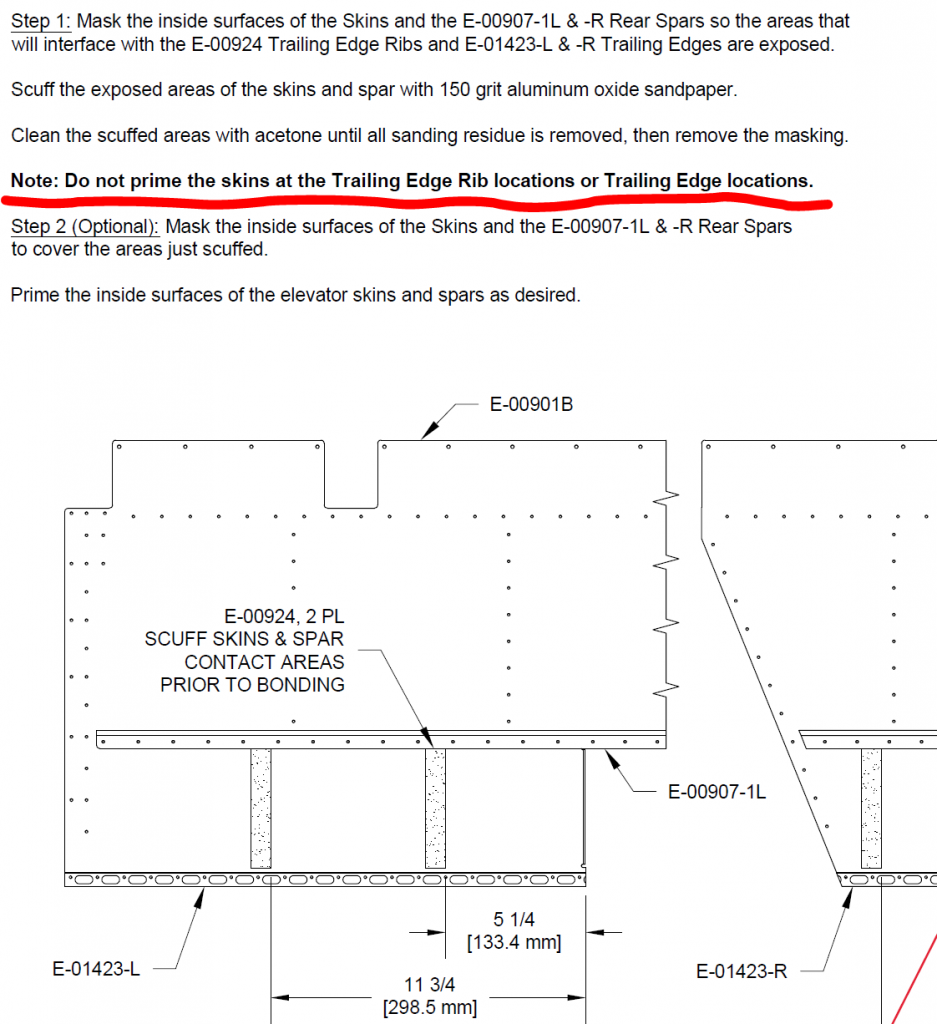

Last week, since almost all of the parts had been fit, trimmed, and deburred I thought I’d be slick and go ahead and prime everything. I’d read somewhere that the plans eventually assume you know when to prime and don’t continue to call out the priming step (whether or not this is true I have yet to determine), and I thought I’d reached that point. I had not reached that point. You see, the plans tell you when to prime, and they apparently tell you when not to prime because an additional step is needed before priming:

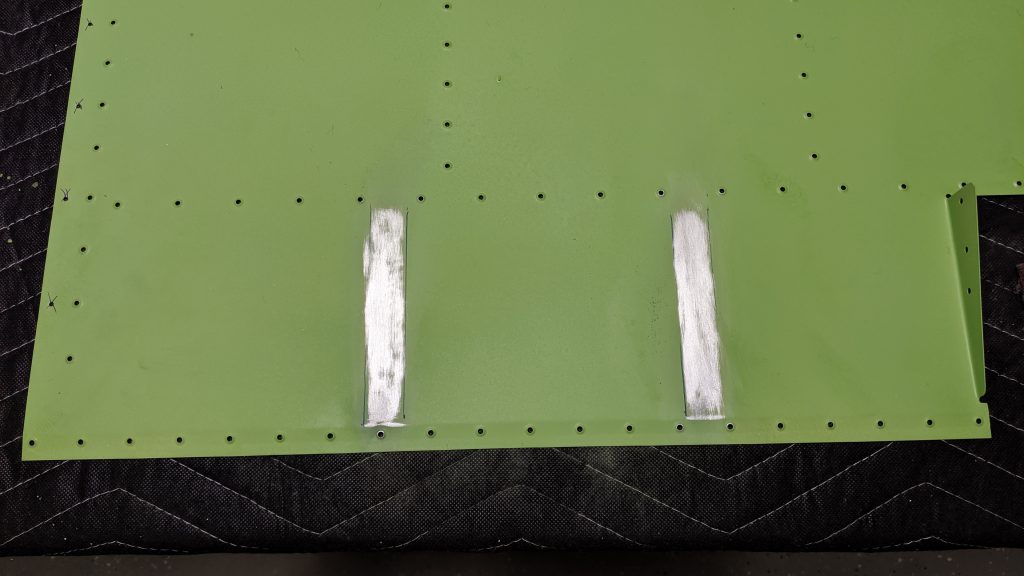

So now I have two skins that have been primed without the masking where the foam ribs will be. So that last part of tonight was beginning the effort to sand off the primer in the rib and spar locations:

It’s going to take some elbow grease, and honestly this primer is probably tough enough to hold a bond, but I think sanding it off and bonding to bare aluminum per the plans is the right call.

Today’s lesson: follow the plans and don’t get cute by skipping ahead!