Holy Deburring, Batman!

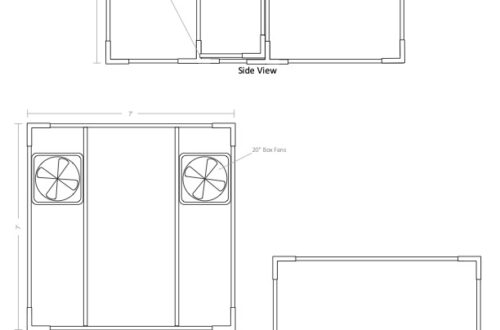

Not a whole lot of progress today. Some more fitting of parts, some deburring, etc. Nothing really exciting. My initial feeling is that this part of the build is going to go quickly; it’ll be interesting to look back on this and see just how right or horribly wrong I am! Anyway, this is pretty much what the aft fuselage looks like at this point:

Section 10 seems to call out priming a lot more consistently than previous sections, so I decided to go with a different approach to priming and prepping this time. Rather than work through the plans until I come to a priming step and then prime those parts, I worked through the plans until I got to what I considered a logical stopping point, skipping the priming steps.

So I fabricated, assembled, match/final drilled, deburred, and scuffed all the parts until the skin riveting begins on page 10-13, and will prime them all in one big batch tomorrow if the weather holds out. I think this method will work well for my building style, and it gets most of the (dreaded) priming out of the way all at once.

One other thing that might be of value: Mitchell’s Abrasive Cord:

This stuff is fantastic for all the small nooks and crannies of these side ribs! I bought the 50 Round, 180 grit on the suggestion from a local builder and it is perfect for deburring tight spaces. I’m also probably going to get the flat abrasive tape for thinner areas like the small gaps between flanges on curved surfaces. Make sure you pick up the aluminum oxide version, lest ye be plagued with galvanic corrosion!